Biologics, clinical trial samples, and a wide variety of classes of pharmaceuticals and medical items are especially sensitive to heat, humidity, and other environmental conditions. Annual losses due to improper handling exceed $35 billion – what can be done to halt this trend?

The worldwide medicines market is expected to surpass $1 trillion in value by 2022, owing to an ageing population in industrialized countries and increased income in emerging ones. Biologics, such as those used in gene therapy, are likely to account for a growing percentage of this industry. Given these growing tendencies, losses are likely to increase as well unless proactive logistic systems are established to safeguard commodities during transportation and storage. Improving existing supply chains to include precise temperature monitoring, cold chain monitoring, and data logging can help you maintain the integrity of your product, save money, and provide better care for patients.

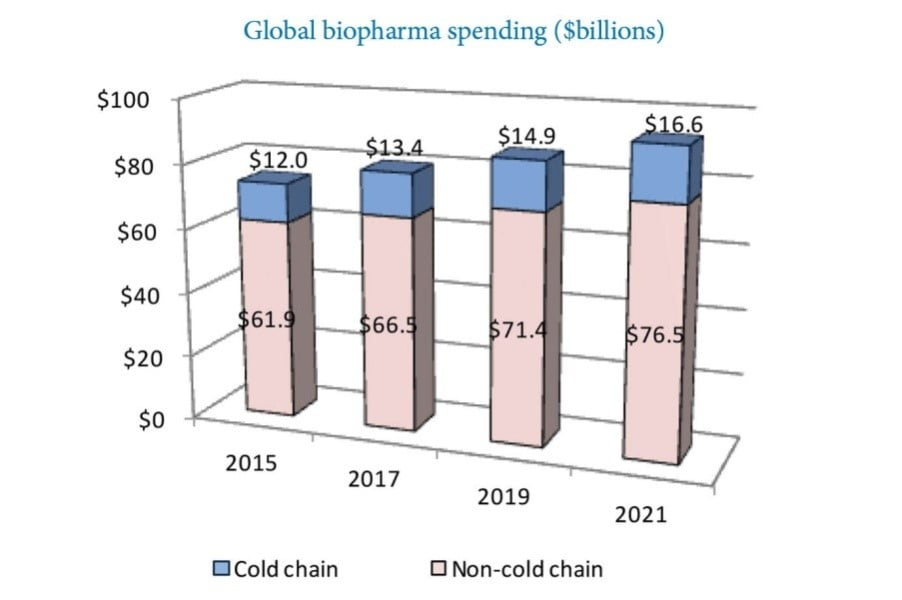

Globally, cold-chain logistics expenditures totaled more than $13 billion in 2017 for biopharmaceutical items alone. Between 20% and 40% of the products covered in that estimate are destroyed before they reach the end customer. With global pharmaceutical spending increasing at a breakneck pace, the global total of pharmaceutical losses is enormous.

The typical online pharmacy process

What normally occurs when a patient obtains medications through an online pharmacy is as follows:

– They consult a physician and obtain a prescription.

– They consult a physician and obtain a prescription.

– They receive the drug via mail from a licensed pharmacy, where pharmacists are available to answer any questions they may have regarding the purchase.

The portion that end customers do not see is the entire supply chain process that occurs between filling and receiving the prescription: the online inventory must be handled (including protection and compliance with applicable safety requirements) in order to give a pleasant customer experience. This means that anyone operating an internet pharmacy must be skilled at interacting with suppliers and transporters. Additionally, they should spend in monitoring and reporting data related to their pharmaceutical supply.

However, as I mentioned in the introduction, much of the supply chain can be jeopardized throughout the shipping process.

Problem: the growing complexity of the healthcare industry

Pharmaceutical items are more sensitive or vulnerable to a larger variety of situations than practically any other type of product. Biologics, clinical trial samples, and a wide variety of medicine and medical product types are particularly sensitive to heat, humidity, and even light. On the other hand, a large number of compounds are likewise vibration and shock sensitive.

While these things have the potential to save lives, they are more difficult to research, create, transport, and store because each product must be as close to perfect as possible. Nobody wants to experience potentially fatal side effects from their drug.

Different raw materials and final commodities may require storage at a range of temperatures in order to preserve their effectiveness. Any change in this temperature or improper handling of the product may permanently spoil it. This could result in ineffective immunizations, the need to discard medications and other temperature-sensitive products, or the loss of critical data from clinical trials. Apart from this financial loss, you may face reputational harm and regulatory scrutiny.

Is shipping damage a significant concern? Most emphatically, yes!. Even if the number is tiny, each item that does not arrive in one piece is inefficient. However, it is not a negligible number. It’s self-evident that you require a system that is adaptable to the changing difficulties facing the healthcare business.

According to an article published in the journal Pharmacy and Therapeutics, it is impossible to determine the precise quantity of damaged pharmaceutical goods. That is because the true figure would include things that are delivered to the end user but are less effective than they should be. The figures are certain to fluctuate according to who and how they are estimated. According to other reports, the figure is at least 20%, if not greater.

Losing more than a fifth of any resource is unacceptably high, both economically and environmentally. At that point, it’s definitely preferable to simply have 20% less company overall, as you’ll save on manufacturing, shipping, and warehousing costs.

Damage can be caused by a multitude of factors. Included are the following:

– Packaging that has been dropped throughout the picking, packing, shipping, and receiving processes

– Packaging that has been dropped throughout the picking, packing, shipping, and receiving processes and this does not simply imply maintaining a cold storage environment for medications. Certain items must be kept at room temperature. Certain items must be kept chilled. Several others require freezing. And many cannot be permitted to go into a state of hibernation.

– Light exposure, which can damage certain items

– Incorrect humidity settings in the freight compartment, which may cause humidity-sensitive goods to tilt or fall over.

Solution – Cold chain Logistics: Adopt or Improve

Whether your medical supplies require consistent room temperature storage or must be cooled, frozen, or deep frozen, cold chain logistics can help ensure temperature monitoring and management at every stage of the process. Cold chain logistics is the management of a supply chain for commodities that must maintain specific temperatures and/or humidity levels. While this has long been a staple of the food sector, with refrigerated trucks and storage facilities for perishable goods, this type of supply chain is also critical in the healthcare industry.

The different aspects that need to be considered by the manufacturer, retailers, and sometimes even the end-customer, include:

– Methods of storing and managing refrigerated and frozen vaccines

– Considerations for equipment such as storage units and thermometers

– Cold chain management strategies

– Routine storage and handling procedures

– Methods of storing and managing refrigerated and frozen vaccines

As the healthcare business evolves, technical advancements must extend beyond the research and development phase to ensure manufacturing and distribution can keep up with the cutting-edge nature of these products. Cold chain systems that combine temperature monitoring and data logging have the ability to significantly improve the integrity of these items, as well as reduce waste, save money, and improve health and safety.

The best way to ensure the safe arrival of pharmacy freight is to implement monitoring as part of the shipping process. This is precisely why data logging is critical for online pharmacy operations.

Important components include:

-Data recording devices that record information such as temperature, vibration, and humidity.

-Devices that are installed in production plants, warehouses, transportation vehicles, or on the product to monitor temperature and other parameters.

-Advanced gadgets equipped with GPS and RFID for real-time data updates

-Light sensors included in packages to ensure the product has not been tampered with

-Software that captures and analyses all data from the data loggers

-Packaging equipped with temperature monitoring that can actively modify the temperature of the items as needed

How might data logging assist with any of these issues? It’s straightforward. When you monitor the conditions under which pharmaceutical goods are carried, you may keep track of how frequently and when proper conditions are met. Once you’ve gathered this data, you may utilise it to help prevent future occurrences and improve shipping conditions.

Apart from really damaged items, many products become unsafe to use when they deteriorate. As a result, even a suspicion that a product is unusable results in its destruction, merely owing to the hazards given by a lack of knowledge about whether the thing is safe to use or not.

Now, suppose you could more precisely assess whether a single component of your shipment is still usable. Simply raising the monitoring precision from one to two measurement points enhances the likelihood of determining that only a fraction of the shipment is unsuitable. For instance, what if, on average, only half of the contents of your ruined shipments are truly ruined? This anticipated 20% loss is immediately halved.

In a million-dollar-a-year shipping firm, this may mean saving up to $100,000 through a modest investment. The more exactly you can demonstrate that a product is useable, the less likely you are to lose it due to mishandling. Even a small, visible indicator of integrated monitoring promotes proper package management.

Quality assurance increases trust

As a result, reputation and end-customer trust are critical. A critical component of operating a successful online pharmacy is having a strong brand presence and a favorable public perception. Given that the pharmaceutical industry’s mission is to help people live healthier lives, it is critical that medications arrive in perfect condition. Being aware of every link in the supply chain is the only way to ensure that the quality of your products is guaranteed.

When you use a suitable data logger to monitor what your products go through during shipping and storage, you can not only be certain of their validity, but also show the data to any authorities who inquire about your operations, and even to end users if the logger is exceptionally efficient .Transparent operations provide your business the confidence necessary to attract new partners and consumers – and a positive reputation in general.

There are numerous types of data loggers available, however for pharmaceutical transport purposes; it is advisable to avoid standalone recorders that require manual data transfer to a computer. That is inefficient and time consuming. Rather than that, the ideal option is to use a wireless logger connected to a cloud service. It enables rapid data uploads for immediate visibility to everyone who need access to the data.

Conclusions

Effective data logging is critical for any activities that rely on the cold chain, or for any temperature-sensitive logistics in general. While the cost may appear to be an additional expense at first, merely knowing which products may be utilized and which cannot can result in a significant increase in your bottom line simply by reducing the number of products that must be considered ruined due to uncertainty. On the other side, having all of this data on how your operations are performing enables you to further enhance them and increases your transparency in the eyes of authorities, partners, and consumers.